The manual sorting of waste materials is one of the toughest jobs in the industry. In order to create humane working conditions, we at INTEGRA are setting new standards in reprocessing with the advanced MSK4 sorting station.

The special feature of the new Integra sorting cabins is the frequency controller for different belt speeds of 0.17 to 0.6 meters per second. Depending on the material (building rubble, residual waste or even slag) and the number of sorting workstations, the frequency-controlled drive always remains flexible in order to achieve the best sorting results. In addition, the sorting cabin can be easily implemented in an existing system in terms of the control system and can also be controlled externally.

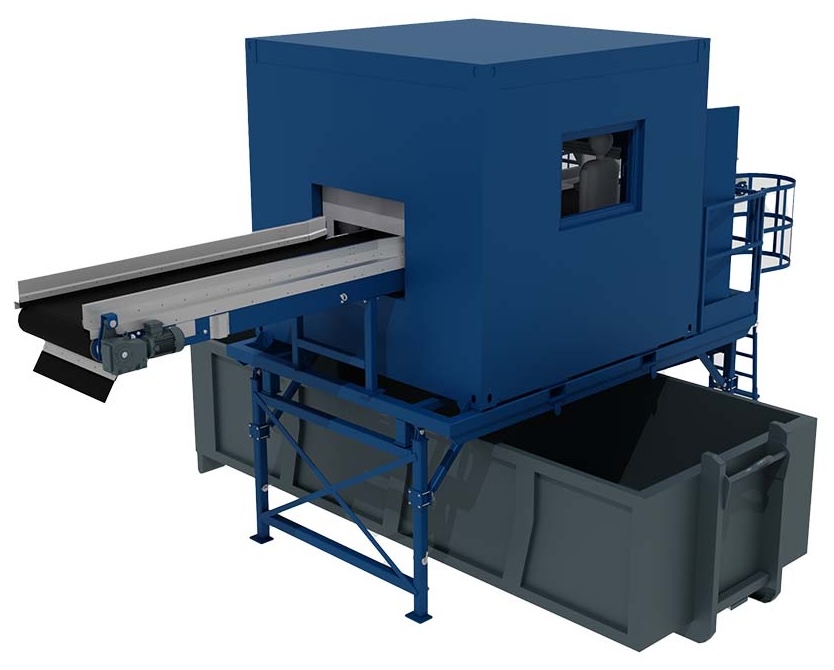

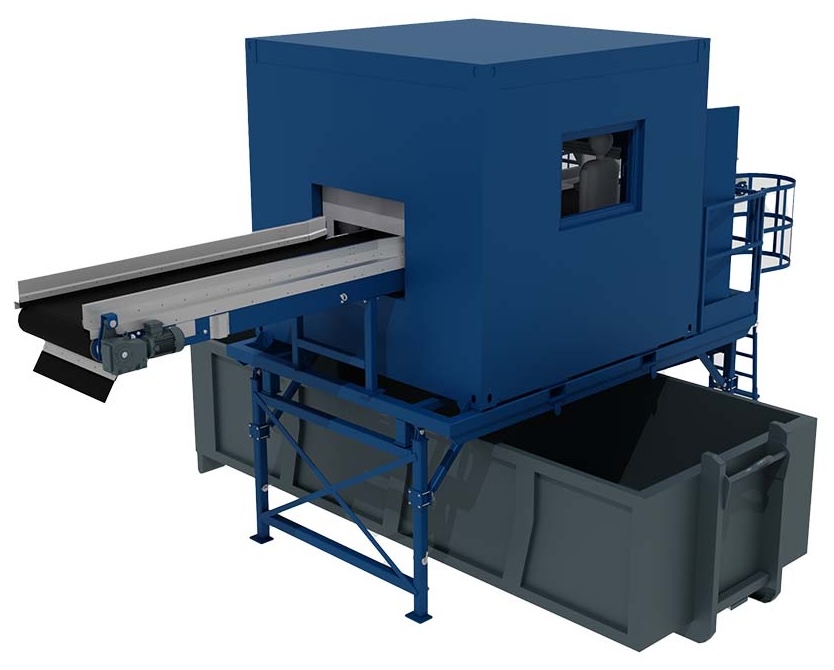

Sorting cabin 3000 x 3000 mm

Sorting cabin 4500 x 3000 mm

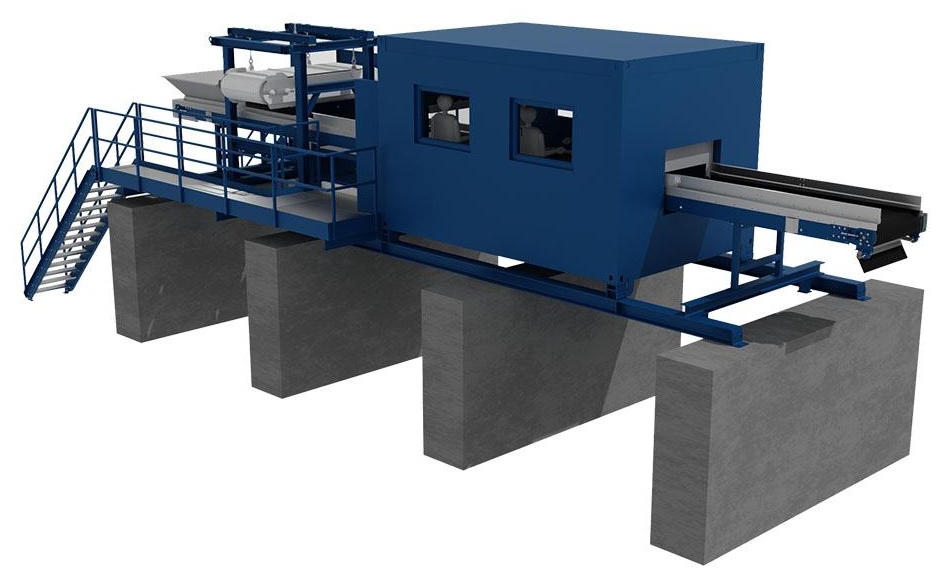

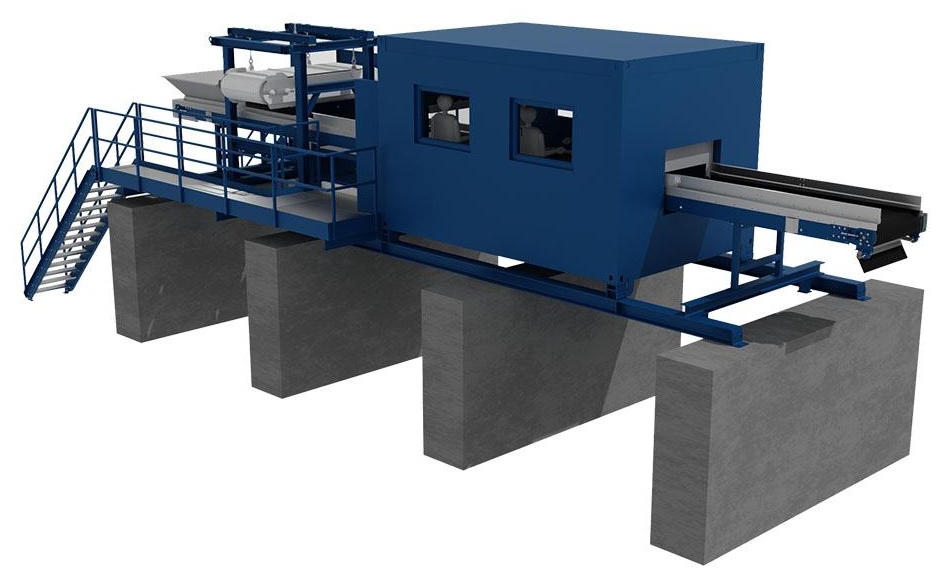

Sorting cabin 4500 x 3000 mm

Sorting cabin 4500 x 3000 mm

The 3000 x 3000 mm sorting cabin offers space for a total of 2 workstations.

In order to integrate the sorting cabins perfectly into existing systems, the height of the cabin can be adjusted in 20 cm steps up to 60 cm.

The material feed hopper has a width of 1400 mm, the belt width can be selected between 800 mm or 1000 mm with a total length of 8000 mm. A chute size of 700 x 400 mm for the sorted material guarantees a smooth workflow.

The insulated stations can of course be equipped with heating or air conditioning, and the position of windows, doors and access stairs can be individually selected. With transport dimensions of 8300 x 3000 x 3180 mm (L x W x H) and a total weight of 5 t, the MSK2 sorting station can be used quickly and flexibly at different work locations at any time.

The large 4500 x 3000 mm unit offers space for a total of 4 workstations.

In order to integrate the sorting cabins perfectly into existing systems, the height of the cabin can be adjusted in 10 cm steps up to 60 cm.

The material feed hopper has a width of 1400 mm, the belt width can be selected between 800 mm or 1000 mm with a total length of the sorting belt of 8000 mm. A chute size of 700 x 400 mm for the sorted material guarantees a smooth workflow.

The insulated stations can of course be equipped with heating or air conditioning, and the position of windows, doors and access stairs can be individually selected. With transport dimensions of 8300 x 3000 x 3180 mm (L x W x H) and a total weight of 5.8 t, the MSK4 sorting station can be used quickly and flexibly at different work locations at any time.

The large 4500 x 3000 mm unit offers space for a total of 4 workstations.

The steps of the sorting cabin provide easy access and can be removed quickly and easily. With the additional feed conveyor, air classifiers, screening machines, crushers, etc. with a lower discharge height can also feed material into the sorting cabin.

The support legs are folded in for transportation, resulting in a transport height of 3180 mm. The distance between the floor and the lower edge of the sorting cabin is 2900 mm, so that the cabin can easily stand over a 2800 mm concrete block wall or over two roll-off containers, depending on requirements.

The material feed hopper has a width of 1400 mm, the belt width can be selected between 800 mm or 1000 mm. A chute size of 700 x 400 mm for the sorted material guarantees a smooth workflow.

The insulated wards can of course be equipped with heating or air conditioning. The position of windows, doors and access stairs can be individually selected. With transport dimensions of 9500 x 3000 x 3180 mm (L x W x H) and a total weight of 6.5 t, the MSK4 T sorting station can be used quickly and flexibly at different work locations at any time.

The large 4500 x 3000 mm sorting cabin offers space for a total of 4 workstations. The stairs of the sorting cabin allow easy access and can be dismantled quickly and easily.

The material feed hopper has a width of 1400 mm, the belt width can be selected between 800 mm or 1000 mm. The sorting belt has a total length of approx. 12 m. A chute size of 700 x 400 mm for the sorted material guarantees a smooth workflow.

An overband magnet is located between the material feed and the sorting house, which sorts out ferromagnetic components in advance and transports them to the box below.

The sorting system is installed on four concrete block walls.

The insulated wards can of course be equipped with heating or air conditioning. The position of windows, doors and access stairs can be individually selected. With transport dimensions of 12500 x 3000 x 3180 mm (L x W x H) and a total weight of 7.5 t, the MSK4 TM sorting station can be used quickly and flexibly at different work locations at any time.

The sorting workstations are designed with particular attention to ergonomics and safety in compliance with the Occupational Health and Safety Act. The chutes can be fitted with a flap that can be opened using a foot pedal. This allows containers to be changed during operation and reduces the ingress of external air.

INTEGRA Windsifter GmbH