We carry out all phases of system construction – from the initial consultation to detailed planning and design through to installation and commissioning.

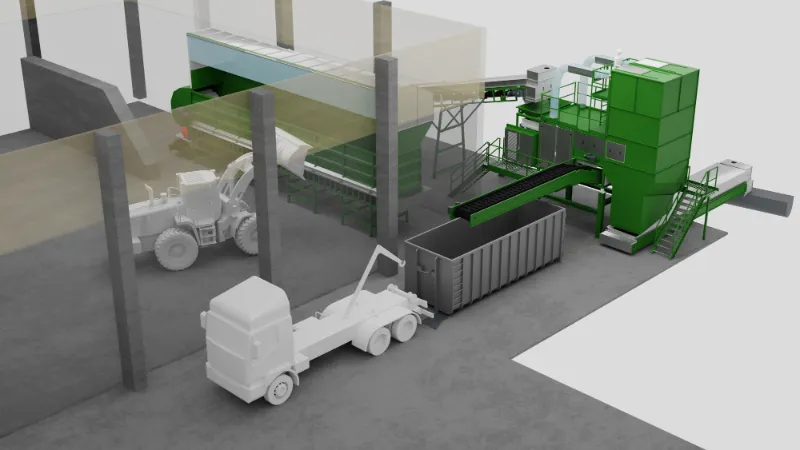

The development of an economical waste sorting system is absolutely customized work. Many individual components must interlock smoothly to guarantee a safe and fast material flow.

The most important course for an efficient system is already set in the planning phase. Together with our customers, we develop 3D visualized concepts using state-of-the-art software and thus guarantee complete transparency.

With our many years of experience and in accordance with VDI 2221, we develop machines and systems in close cooperation with our customers. With the special feature that these are efficient and durable in operation even under the most difficult conditions.

Once the concept has been successfully developed, our machines are designed in detail by our design department to meet your individual requirements.

Thanks to our high level of vertical integration within metal processing, we can guarantee a high standard of quality. In addition, we only use technically mature components that have been tried and tested in our machines for years.

INTEGRA is characterized by a high degree of flexibility in design and production. As specialists in the recycling industry, there is hardly a project that cannot be implemented.

Assembly and commissioning are also part of our range of services. Before delivery, each machine is tested at INTEGRA and then installed by our assembly team on the customer’s premises. In cooperation with our suppliers, we are able to deliver turnkey systems.

Service and customer satisfaction are our top priority. However, should there be a problem with one of our machines, we react immediately to avoid downtime.

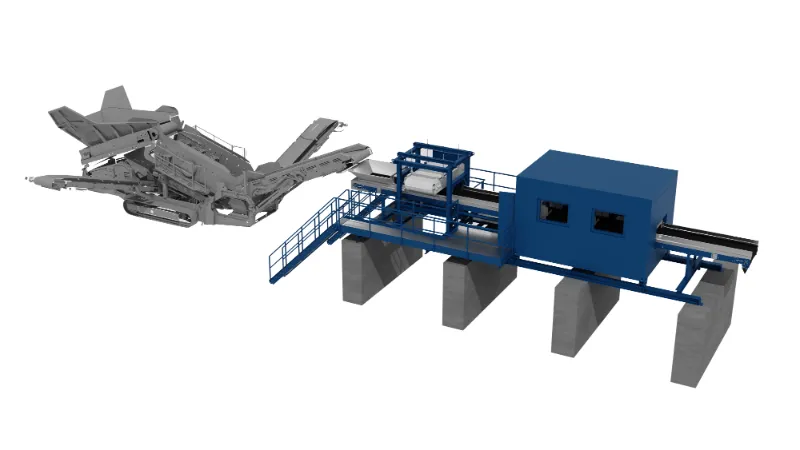

Our product portfolio includes advanced recycling systems that we integrate precisely into existing systems using the latest 3D scanning technology.

Our wind sifters, which have been optimized for years, offer a wide range of possible applications. In addition to the planning, development and commissioning of new systems, INTEGRA also specializes in the retrofitting of wind sifters.

Using the latest 3D scanning technology, we can precisely measure existing systems and integrate our air classifier, including conveyor technology, into your treatment process.

With the constant further development of state-of-the-art processing plants and separation processes, the requirements for precise dosing systems are also increasing.

With our latest development, we dose and store material for laser-induced plasma spectroscopy (LIPS) systems, for example, at a continuous throughput rate of 4-12 t/h. The unique, uniform and continuous dosing makes such throughput rates of downstream sorting systems possible in the first place.

With our large portfolio of different sorting cabins, there are no limits to mobile manual processing. The same also applies to the material.

Our mobile sorting systems can be set up and dismantled quickly and are flexible in use.

INTEGRA Windsifter GmbH